I recently started a new chapter in my life by becoming a teacher, and I’ve discovered that small-scale projects can be incredibly useful in the classroom. These miniature tools can serve as excellent teaching materials, particularly for students studying mechatronics and engineering. They offer hands-on opportunities to assemble and disassemble machines, perform maintenance, troubleshoot failures, and work with simple electrical diagrams.

These little machines provide a wealth of learning opportunities for students. They’ll not only learn how to 3D print the components, giving them an understanding of additive manufacturing, but they’ll also gain experience in preparing the parts by removing plastic imperfections. Students will then follow assembly steps, screwing parts together, using bearings, and wiring all the electrical components. They’ll work with switches, motors, and more, making it a truly enriching experience that combines theory with practical application.

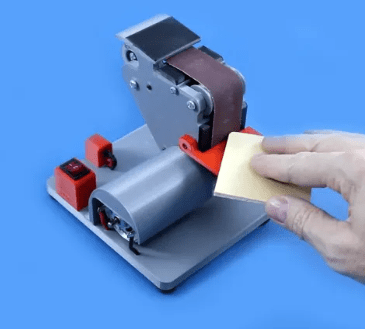

Outfitting a full workshop can be costly and unnecessary if you’re working on small-scale projects. For those focused on miniature machining, building a set of tiny tools, like [KendinYap] did, could be a great alternative. In a video, [KendinYap] demonstrates the effectiveness of miniature tools such as an electric sander, table saw, drill press, and cut-off saw. Despite their small size, these tools are highly useful for delicate tasks. The tools are primarily made from 3D-printed parts and powered by simple DC brushed motors, making them ideal for small-scale model-making enthusiasts and an excellent educational resource for my students.

You can fin the whole projet here:

https://www.printables.com/model/719862-mini-sanding-and-sharpening-machine

Leave a comment